What is The Difference Between Electrical Trunking and Conduit Pipe?

Between electrical trunking and conduit pipe, the difference is that trunking provides a more versatile solution for managing and routing electrical wires in various applications, while conduit pipe offers a protective electrical casing for wiring that is often required in specific projects.

Trunking can typically be installed without the need for additional materials or tools to attach it, making it a convenient choice.

In contrast, conduit systems, which may be made from materials such as aluminum or PVC conduit, involve a more structured installation process to ensure the safety and protection of the wires within.

What is trunking in electrical installation?

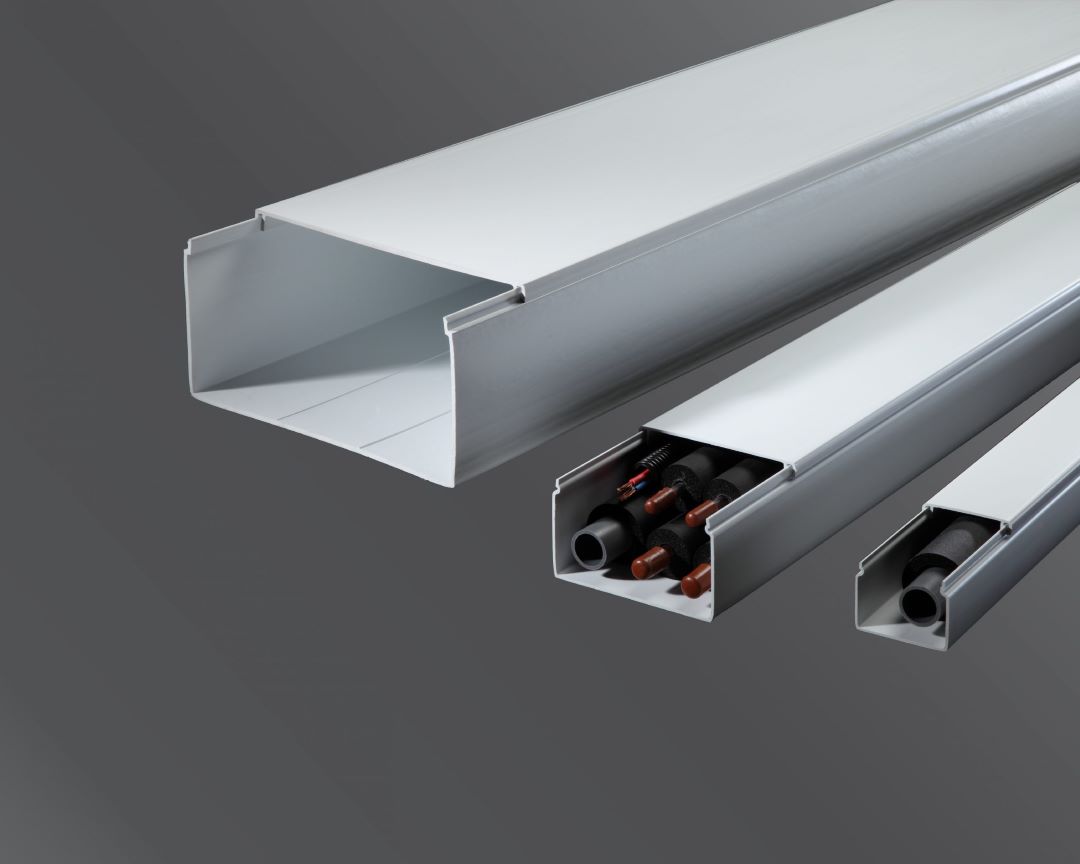

In electrical installation, trunking is referred to as a protective routing system for electrical cables, designed to manage and secure wiring within a building.

It is required for various applications across projects, accommodating the exchange of electrical cables while effectively supporting the weight of multiple wires.

Wire trunking systems ensure that installations are compliant with safety standards, allowing for organized and efficient management of electrical pathways in both residential and commercial buildings.

What are the types of trunking in electrical installation?

In electrical installation, the types of trunking include basic plastic cable trunking in grey, black, or white, galvanized metal trunking, decorative and colored cable trunking, or self-adhesive trunking.

Basic plastic trunking is commonly used due to its versatility and ease of installation, allowing electricians to easily attach and conceal electrical cables.

Galvanized metal trunking, on the other hand, provides added durability and protection, particularly in environments that require robust solutions.

Lastly, decorative trunking not only serves a functional purpose but also enhances the aesthetic appeal of spaces, while self-adhesive options simplify the installation process by eliminating the need for additional tools and materials.

Each of these trunking types plays a vital role in keeping electrical installations organized and safe.

What are the different electrical trunking sizes?

The different electrical trunking sizes are manufactured in a range of sizes, including common dimensions such as 16mm x 16mm, 25mm x 16mm, 38mm x 25mm, 40mm x 25mm, 50mm x 50mm, 75mm x 50mm, 75mm x 75mm, and 100mm x 40mm.

Selecting the appropriate size ensures that wires can be easily organized and installed while considering the weight they will support.

For instance, the trunking size for a 2.5mm cable may require a larger profile to manage the installation effectively.

A trunking size chart can provide valuable guidance in determining the best fit for your electrical PVC trunking sizes or GI trunking sizes, ensuring optimal performance and compliance with wiring regulations.

What are the advantages and disadvantages of trunking wiring system?

The advantages and disadvantages of trunking wiring system include a variety of factors that impact its application in electrical installations.

On the positive side, trunking systems help to keep cables organized and secured, reducing tripping hazards in both residential and commercial buildings.

They provide a protective channel that safeguards electrical cables from moisture and water damage, which is vital in preventing corrosion and extending the lifespan of conductors.

Additionally, trunking can help prevent electrical fires and shocks by offering a safe pathway for wiring, making it suitable for various types of applications.

However, some disadvantages may arise, such as the potential for increased installation costs and the need for regular maintenance to ensure that the trunking remains clean and free from debris, which can hinder the efficient operation of conductors.

What is the difference between trunking and conduit?

Between trunking and conduit, the difference is that trunking typically provides a larger and more secure system for managing multiple electrical cables, while conduit, often in the form of tubing or cable conduit pipe, is usually preferred for protecting individual wires.

Trunking installations can be heavier and may have a higher initial cost, this suggests that they might be more expensive. However, it's necessary to clarify which is cheaper by cost comparison to avoid contradiction.

Trunking offers various advantages in terms of length and flexibility of cable management in buildings.

The applications of trunking are more diverse, allowing for easier access to wires for maintenance or alterations, whereas conduit is better suited for environments requiring stringent protection against environmental factors.

Both systems are installed based on the specific structure and electrical requirements of a project, making them similar in purpose but distinct in design and functionality.

Additionally, trunking systems can accommodate a wide range of wire sizes and types, allowing for efficient management of electrical cables across various applications, whereas conduit is typically limited to specific cable types, seeking to securely encase and protect them.

What is the price of trunking pipe? Metal vs PVC Conduit

The price of a trunking pipe is influenced by various factors including the material, length, and weight.

For projects requiring electrical wiring installations in buildings, metal trunking tends to be more expensive due to its durability and ability to resist damage, making it a preferred choice for applications where protection is critical.

In contrast, PVC conduit is generally more cost-effective, providing an easily manageable solution for less demanding environments.

Prices for PVC conduit tubing can vary, but both metal and PVC systems require specific fittings to attach to existing channels seamlessly.

For instance, a basic length of PVC conduit might cost around S$3 to S$5 per meter, while metal trunking can range from S$8 to S$15 per meter based on the required specifications.

Budgeting for these materials is essential when evaluating the overall cost of electrical installations in your cart for future projects.

What is the difference between conduit and trunking?

Between conduit and trunking, the difference is that trunking serves as the framework for each electrical installation, while conduits are designed to cover the cables that run outside the trunking system, extending all the way to outlet boxes.

Trunking provides a structured way to store and organize wires, ensuring that they remain secure and protected from damage, while conduits safeguard the cables against environmental factors such as rain and water.

In trunking systems, it's essential to attach an inlet for ease of access and to accommodate the required weight of various installations, which can include light communications equipment.

Although trunking systems can be cost-effective, a conduit system may be heavier and, in some applications, could be seen as more costly.

Using the appropriate tube and nut fittings, both trunking and conduit work hand in hand to create a comprehensive electrical framework that meets the demands of modern installations.

What is electrical conduit pipe used for?

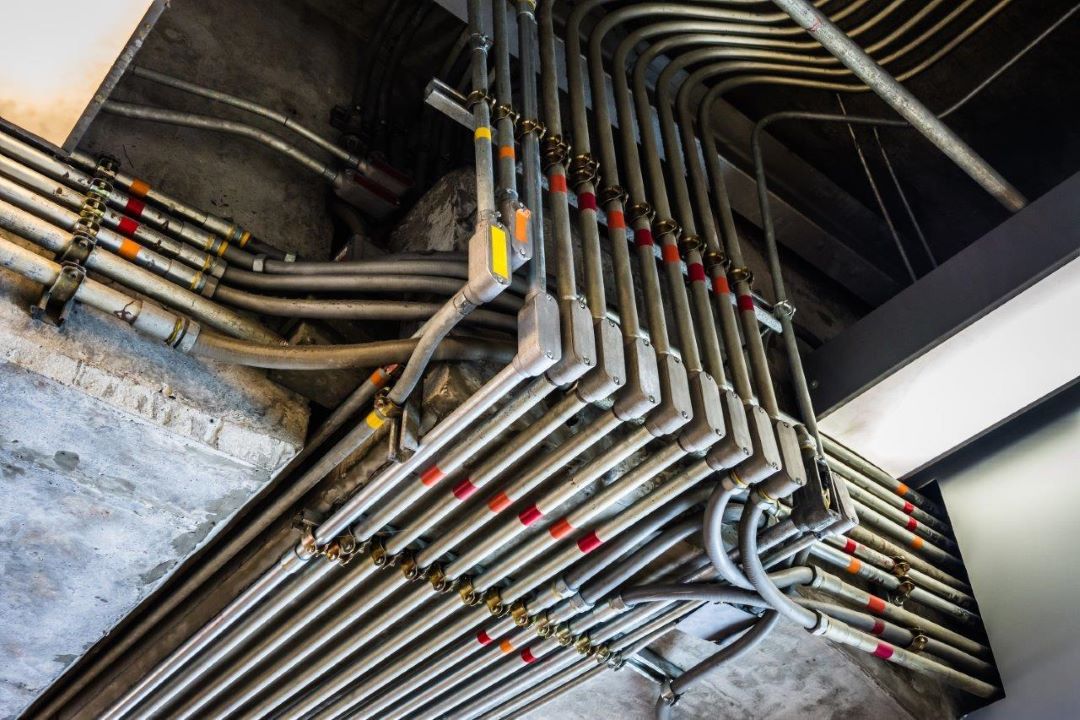

Electrical conduit pipe is used for various types of wiring systems, providing protection and support for new wiring installations.

When secured properly, these conduits protect electrical equipment from environmental factors, particularly in outdoor or concrete building projects.

The lengths and sizes of conduit pipes can vary based on the specific requirements of a project, and they are manufactured from different materials to suit diverse applications.

When planning an installation, it is crucial to understand the differences between conduit and trunking, as well as the various fittings, such as nuts and connectors, that may be required.

Many stores offer a cart for easy selection of the necessary conduit pieces, ensuring all components are readily available for efficient exchange during installation.

If you're eager to tackle electrical trunking DIY projects, be sure to check out our guide on how to make a 90-degree elbow in electrical conduit pipe to ensure a seamless fit and professional finish.

What are the two types of electrical conduit? Types of Electrical Conduit in Conduit System

The two types of electrical conduit are metallic and non-metallic electrical conduit, each designed for specific applications and requirements.

Metallic conduits, such as Rigid Metal Conduit (RMC), Galvanized Rigid Steel (GRC), Intermediate Metal Conduit (IMC), and Electrical Metallic Conduit (EMT), are durable and suitable for environments where impact resistance is required.

These conduits provide robust protection against moisture and corrosion, making them ideal for projects in various applications, such as building distribution systems for electrical wires and conductors.

Non-metallic alternatives, including Rigid Non-Metallic Conduit (RNC) and PVC conduit, offer a lighter weight solution, which can be advantageous for electrical wiring services and conduit installation, as they are easier to carry and work with.

Both types come in various lengths and fittings, allowing flexibility in design and assembly, whether in outdoor or indoor environments.

Though PVC tubing can be more cost-effective, metallic options provide superior durability for demanding conditions, ensuring long-lasting performance and reducing the frequency of replacement.

This comprehensive selection of conduits enables efficient organization and protection of electrical systems, which are critical for any project’s success.

What is meant by electrical trunking?

Electrical trunking is an enclosure usually with a rectangular cross section designed to protect and manage electrical cables within various environments.

This system is commonly installed in buildings to facilitate the organization of wiring and ensure a tidy appearance.

Trunking offers flexibility in design and is used in a range of applications across multiple countries on both new and retrofitted projects.

Similar to conduit systems, trunking allows for the easy installation and modification of electrical systems, adhering to standards such as BS: EN.

Its materials, such as aluminum and PVC trunking, contribute to its durability and adaptability for future expansions, making it a preferred choice for many builders and electricians.

If you're eager to tackle electrical trunking DIY projects, be sure to check out our guide on how to make a 90-degree elbow in electrical trunking to ensure a seamless fit and professional finish.

After completing your DIY project, it's important to explore various methods to effectively conceal your HDB electrical trunking, ensuring a clean and visually appealing environment while maintaining accessibility for future modifications. Check out what are the ways to conceal your HDB electrical trunking!