How to Make a 90 degree Elbow in Electrical Conduit Pipe?

In electrical conduit pipe, you can make a 90 degree elbow by carefully measuring and cutting the conduit to ensure a precise fit, which is essential for maintaining the integrity of the electrical system.

This process involves using specialized tools to create an elbow conduit that seamlessly directs wires or cables around obstacles.

Proper installation of the electrical conduit 90 degree elbow is crucial for efficient wiring and compliance with electrical codes, making the 90 degree elbow conduit an important component in any electrical installation.

What is a great 90 degree conduit bend calculator?

A great 90 degree conduit bend calculator is available online at various sites like CalcTool, where users can input the specific dimensions and measurements of their PVC conduit to obtain accurate bend results.

This tool simplifies the process of calculating the necessary angles for creating precise bends in electrical conduit elbow applications, ensuring the integrity and functionality of installed products.

By utilising such calculators, electricians and DIY enthusiasts can efficiently plan their projects while reducing material waste and improving overall accuracy.

What is the formula for bending conduit?

For bending conduit, the formula is quite straightforward and essential for ensuring accurate bends, especially for a 90-degree angle.

The inner radius and outer radius are calculated with respect to the wall thickness and outer diameter of the pipe.

To determine the center radius, you can use the formula: center radius = outer radius - O.D/2.

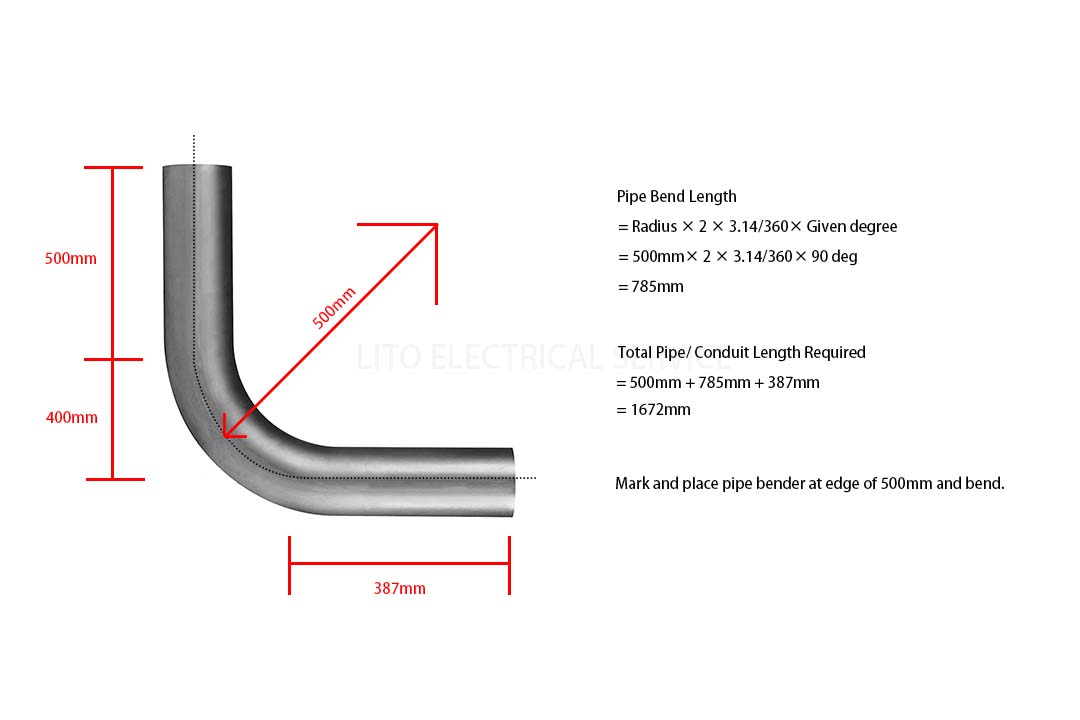

For a given degree of 90, the formula for finding the length of the bend is length = radius * 2 * π / 360 * given degree.

For example, if the center radius is 500mm, the length of the 90-degree angle would be approximately 785mm.

Therefore, the total conduit length required, when combining with other segments, is 500mm + 785mm + 387mm.

This easy approach allows customers to find the dimensions quickly, ensuring that wires can be flexibly attached without hindrance. Utilizing this formula not only simplifies the process for customers but also guarantees precision in every bend made.

What is the pipe bending formula?

The pipe bending formula is to multiply the radius of the bend by the induced angle, then multiply the product by the constant 0.01745. The result is the length of the curved section, which allows you to find the required length of the conduit needed for your installation.

For example, when considering a 90-degree electrical elbow bend, if you have the outer diameter and wall thickness, you can easily calculate this length using the formula.

It's essential for customers to understand the tangent point as it helps determine where the bend should begin.

Additionally, for more complex bends such as 180 degrees, simply multiply the radius of the bend by 3.14 to find the length needed.

A conduit bending cheat sheet can be a valuable tool for wiring projects, ensuring that you can easily attach wires and create flexible routing for electrical wiring services and installations, making it easier to satisfy customers' requirements.

How to make parallel 90 degree bends?

To make parallel 90 degree bends, it's important to understand the specific formula that calculates the required length of conduit that will be bent.

This involves considering the radius of the bend, the tangent point, wall thickness, and the outer diameter of the conduit.

For an easy approach, you can use the formula: Total Length = (Radius + Wall Thickness) x π + (Outer Diameter x 2), which helps ensure you find the correct lengths needed.

When creating parallel kick 90s, the spacing between bends is crucial to accommodate flexible wires.

This not only allows for smoother wire attachment but also ensures that customers can easily manage their wiring systems without complications.

Additional diagrams illustrating parallel 90 degree bends can be particularly helpful, providing visual guidance to assist in the bending process.

How to make a 90 degree bend in conduit?

To make a 90 degree bend in conduit, you have the option to use heat or a pipe bender for flexibility and ease of use. When working with PVC or other plastic conduit products, heat can be an effective method.

Begin by measuring the length of the conduit you will need for your project, ensuring you choose a piece that allows for the bend and any elbow connector fittings you plan to attach. For example, if you are bending a 1/2" PVC pipe, you might typically need about 150 mm of straight length on either side of the bend.

Using a pipe bender can make the process even easier. For the same 1/2" pipe, you would set the bender to the appropriate radius for a 90 degree bend, ensuring it accommodates the flexibility of the plastic.

To calculate the total length of conduit required, you can use the formula: Total Length = Straight Length + Bend Length.

If the bend length for a 90 degree angle is approximately 75 mm, you would measure accordingly and determine the overall length needed to work with your (galvanized iron) GI conduit pipe fittings and applications.

How many 90 degree bends are in electrical conduit?

In electrical conduit, there are four 90 degree bends usually allowed per run, according to the NEC (National Electrical Code).

This requirement helps maintain the flow of electrical work while ensuring safety. When working with conduits, such as PVC, it's important to choose bends wisely to make the installation easier and to optimize time.

Finding the right tools and using a cart can make the process much easier, minimizing the physical effort required. Always be mindful of the number of bends, as exceeding this limit could complicate your installation and require additional work to correct.

When considering the four allowable 90-degree bends in elbow electrical conduit, it's also essential to explore effective ways to conceal your HDB electrical trunking, as strategic placement and minimal bends can enhance aesthetics while ensuring compliance with safety regulations. Read up on what are the ways to conceal your HDB electrical trunking?

Can you use a 90 degree elbow in a drain pipe?

No, you cannot use a 90 degree elbow in a drain pipe without considering the potential issues of clogs and blockages, which can significantly reduce flow efficiency.

Utilizing sharp bends can lead to increased wear and tear on your plumbing system and may not meet building code compliance requirements.

When selecting fittings for a drain installation, it's essential to choose components that facilitate a smoother flow, making it easier for waste to move through the system.

To find the right sort of products, you might want to consult a construction guide or the PVC conduit installation manual.

Ensuring that the correct angles and fittings are attached during installation can save time and effort down the line, making your work more efficient and less prone to future problems.

With the right approach, choosing appropriate PVC products for your drains will keep your systems functioning optimally.

How to bend PVC pipe 90 degrees?: PVC Conduit Pipe Bending

To bend PVC pipe 90 degrees, first apply heat to the section of the pipe that needs to be bent. You can use a heating torch or a hairdryer, focusing the heat on the area until the material softens.

This process makes it easier to manipulate the flexible PVC (Polyvinyl Chloride) when heated. Once you achieve the desired softness, carefully bend the pipe into your required shape and angle, ensuring it maintains its integrity without kinking.

Finding the right timing for heating depends on the thickness and type of PVC conduit you're using, so results may vary; always monitor your progress. Using this method not only meets your EMT elbow pipe bending needs but also allows you to customize fittings with ease.

Choosing quality products can significantly enhance your workflow when working with plastic conduits.

Apart from 90-degree conduit pipes, you also need to learn how to make a 90-degree elbow in electrical trunking, as this allows for efficient routing of electrical cables while maintaining a neat and organized installation.

Check out what is the difference between electrical trunking and conduit pipe, as understanding these distinctions can significantly impact your project's efficiency and compliance with safety regulations.